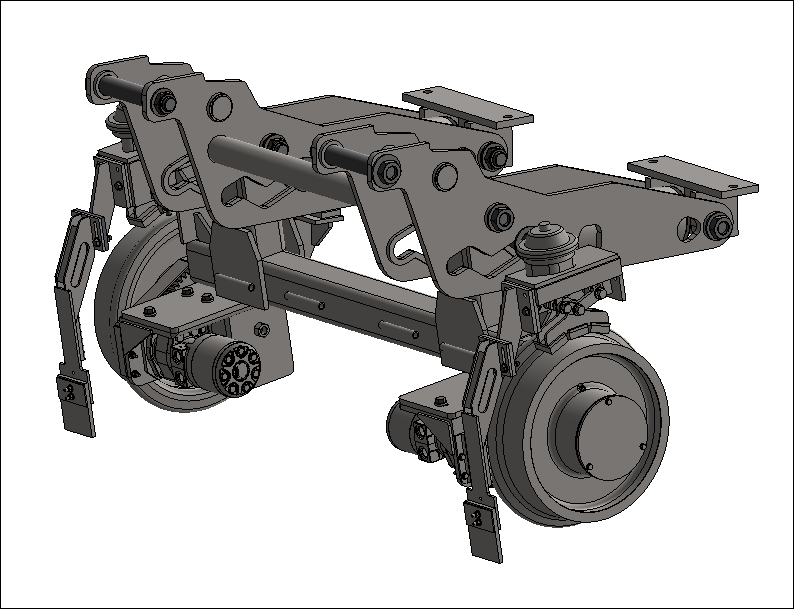

60 Series Self Propelled

36,000 lbs – 66,000 lbs GVWR

Designed for material handler applications the SP-60 integrates the creep drive functionality into the proven design of the Continental G-60 Front Hi-Rail. The twin motors mounted on the front Hi-Rail axle allow the chassis to be moved down the rail in both directions up to 8 MPH. When the creep drive is not needed turn off the hydraulics to disengage the motors and the operator is able to operate like normal. Since the motors are mounted on the hi- rail axle there is no modification to the drive line of the chassis required for the installation. The unit is controlled wirelessly and allows the operator to have control over the parking & service brakes, horn and speed control.

Model:

SP-60 Front Hi- Rail

Capacity:

40,000 lbs.

Type:

Rotary Self Propelled Front

Weight:

Front -1,750

Wheel Diameter:

Tread diameter 16" drop forged AAR profile

Wheel Spindle:

Precision Ground C-1045 steel, 2-3/4" diameter

Wheel Bearings:

Heavy duty tapered roller bearing

Hydraulic Requirements

40 GPM @ 2500 psi. for a maximum speed of 8 MPH.

Locking Mechanism:

Automatic mechanical locks front

Derail Skids:

Standard

Railsweeps:

Standard, front

Insulation:

Track circuit insulation standard

Alignment:

Simple adjustment for toe-in and toe-out, side to side and axle alignment

Speed Restrictions

The SP-60 can travel up to speeds of 35MPH while on rail.

Front and rear air brakes

Track signal shunt kit